Applications and Benefits of PVC Packaging Film

2023-01-09 15:17PVC packaging film is used for sales and transportation of various products, and its main function is to stabilize, cover and protect products. PVC packaging film has relatively good puncture resistance, good shrinkage and corresponding shrinkage stress.

PVC packaging film is widely used in the packaging of various commodities such as wine, food, sporting goods, tableware, electronic appliances, daily necessities, handicrafts, audio-visual products, stationery, toys, doors, plastic hardware, glass ceramics, etc., to make its appearance more distinct It is beautiful, improves the product packaging grade, and protects the product from dust and random flowers. It is an ideal film packaging material at present.

PVC heat shrink packaging machine can be processed and cut at will. It is often used in molds, hydraulic machines, and other parts that need heat insulation. It can also be used for self-made roofs and other parts that need heat insulation. Save energy, reduce heating time, reduce heat conduction to equipment, and have good heat insulation effect.

In the production process of PVC packaging film, it is easy to cool after being stretched in a high temperature environment, and then achieve the purpose of shaping. When it is heated again during use, it retracts to its original position, the heating is uneven, and the degree of shrinkage and size are also different.

The production of PVC packaging film first adopts extrusion blow molding or extrusion casting to produce a thick film, and then fully softens it at the melting temperature, and then stretches it horizontally and vertically.

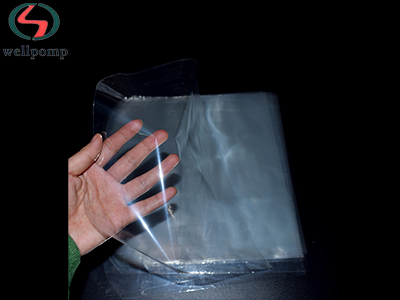

PVC packaging film bag is a kind of packaging material in heat-sealed packaging. Through hot air blowing, the high-transparency packaging film can cling to the surface of the article, so as to improve the product grade, prevent dust and moisture, and make the article show a new packaging effect. Packaging film packaging, the operation method is simple and easy to learn.

The shrinkage effect of the package is flat, the brightness is good, the film stiffness is good after shrinkage, and the package tightens well. The raw material is easy to shrink, and the temperature of the shrinking environment is not high. It can shrink at 40 degrees Celsius, but its strength is greatly affected by the external temperature, and its softness is poor in a low temperature environment.

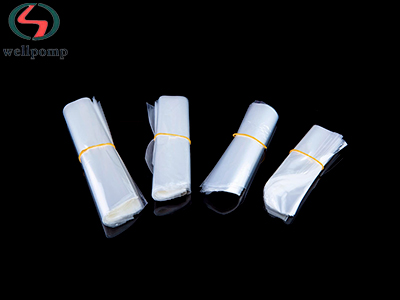

PVC packaging film is widely used in our life. PVC packaging film is made of ethylene-based PVC resin mixed with more than a dozen auxiliary materials and then inflated twice. Its use method is to calculate the circumference according to the size of the packaged object, and convert the folded diameter (folded diameter = 1/2 week) length), and then appropriately enlarge the diameter.

The PVC packaging film is compared with the product specifications of our factory, and the appropriate PVC heat shrinkable sleeve film is selected. Install the casing film on the packaged object, and it will take 6-10 seconds at a temperature of 100°C-160°C (the actual temperature of the casing film is 86°C, and the temperature rise of the packaged object is less than 10°C) .