Hot-pressing sealing method and application method of packaging film

2024-03-28 17:48Let's take a look at the sealing method of packaging film hot pressing:

1. Heat the two contact surfaces of the packaging film to make it in a melting shape, and then increase the pressure to make the contact surfaces become integrated, which can play a series of effects such as packaging and aesthetics.

2. Packaging film manufacturers tell you that resistance heating and pulse heating are two commonly used methods for hot sealing, as well as special wave heating and high-frequency current.

3. Temperature is a factor that affects the sealing effect. If the temperature is too high, it will easily lead to the deformation of the contact surface and affect the appearance. If the temperature is too low, it will easily lead to problems such as lax sealing.

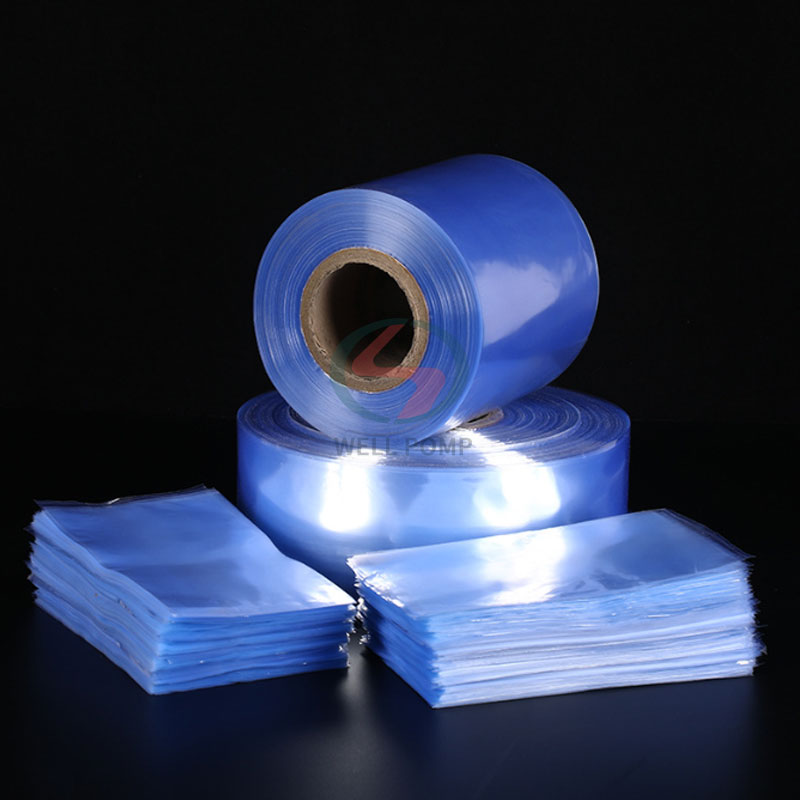

Packaging film was used in industrial packaging from the beginning of industrial production, and then used in food packaging. The packaging film uses the energy that the film is stretched longitudinally or transversely in a high elastic state to be stored in the film, and uses the memory effect of thermoplastics on the shape before biaxial or unidirectional stretching to restore the shape before stretching when it meets heat again to achieve the packaging purpose.

Packaging film sleeve label is a new label printed on plastic film or plastic pipe, which mainly includes common packaging film types such as PE, PVC and PET, and has the following characteristics:

1. When labeling the packaging film sleeve label, there is no need to use adhesive, and the same transparency as glass can be obtained;

2. The printing of packaging film sleeve label belongs to film inner printing, which can protect the imprint and the label performance is good;

3, the packaging film sleeve label is convenient to process, the packaging is sealed and pollution-proof, and the product protection is good;

4. The packaging film sleeve label can provide 360 multi-angle decoration for the packaging container, and can print the product description and other commodity information on the label, so that consumers can understand the performance of the product without opening the package;

5, the packaging film sleeve is close to the goods, the packaging is compact, and the shape of the goods can be displayed, so it is suitable for irregular goods that are difficult to package;

Packaging film is used for the sale and transportation of various products, and its main function is to stabilize, cover and protect the products. Shrinkage film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Because shrink film is often suitable for outdoor use, it is necessary to add UV anti-ultraviolet agent.

The heat shrinkable machine is a small-scale heat shrinkable packaging equipment made according to the standard, which has the characteristics of simple operation, wide application range, good sealing, high transparency and low cost, and is suitable for packaging small and medium-sized products. The heat shrinkable machine and the label-setting machine are used on line to form a label-setting machine production line, which is generally suitable for fully enclosed heat shrinkable packaging of products such as food, drinks, stationery, ceramics, daily chemicals, auto parts, needle spinning, electronic audio-visual products, etc. It is a label-setting shrinking machine in the following packaging line.

If the shrinkage rate of heat shrinkable film is too high or the shrinkage force (including heat shrinkage force and cold shrinkage force) is too high, it will easily lead to the increase of film consumption and too tight, which will lead to the deformation of yogurt cups or the breakage of films; If the shrinkage rate of the heat shrinkable film is small or the shrinkage force is too low, it is easy to appear that the film does not fit the yogurt cup and the packaging is loose, which leads to the easy fall-off of the cup-connected products.

Therefore, before using heat shrinkable film, we should strictly monitor the related shrinkage properties, such as shrinkage, heat shrinkage force, cold shrinkage force and other performance indicators, in order to ensure that the external packaging of yogurt multi-cup is compact and not easy to be damaged, and reduce the packaging cost.

Application method of packaging film:

1. The packaged products should avoid touching sharp objects;

2. During heat sealing, heat shrinkable film should clean the heat sealing parts and seal them cleanly;

3. Do not overfill the contents, but leave a length of 5-8㎝ to facilitate vacuum and heat sealing;

4, stop more than sealing, shorten the temperature of the product. The thermal shrinkage temperature of the product is 85 2℃, and the thermal shrinkage time is 1-2 seconds;

5. Replace the silicone rubber strip, Teflon cloth, heating strip and vacuum pump oil of the vacuum machine regularly to ensure that the vacuum machine is in working condition.