How to distinguish the quality of heat shrinkable film?

2024-04-14 15:08Heat shrinkable film quality identification method:

1. Handfeel identification method: heat shrinkable film, a food with qualified quality, feels smooth and flexible to the touch, and those with stiff and sticky feel are unqualified packages.

2. Immersion identification method: If the qualified packaging heat shrinkable film is placed in a container filled with water, it will float, and those with poor quality or unqualified will often sink to the bottom of the water. Of course, the performance of this method is not improved at present, and many inferior products can achieve this effect through special production processes now.

3. Ignition identification method: heat shrinkable film with good quality is easy to ignite, and the flame is obvious when it burns, while those with unqualified substances are not easy to burn.

When in use, it can save materials, labor and time, and is widely used in papermaking, logistics, chemical industry, plastic raw materials, building materials, food, glass and so on.

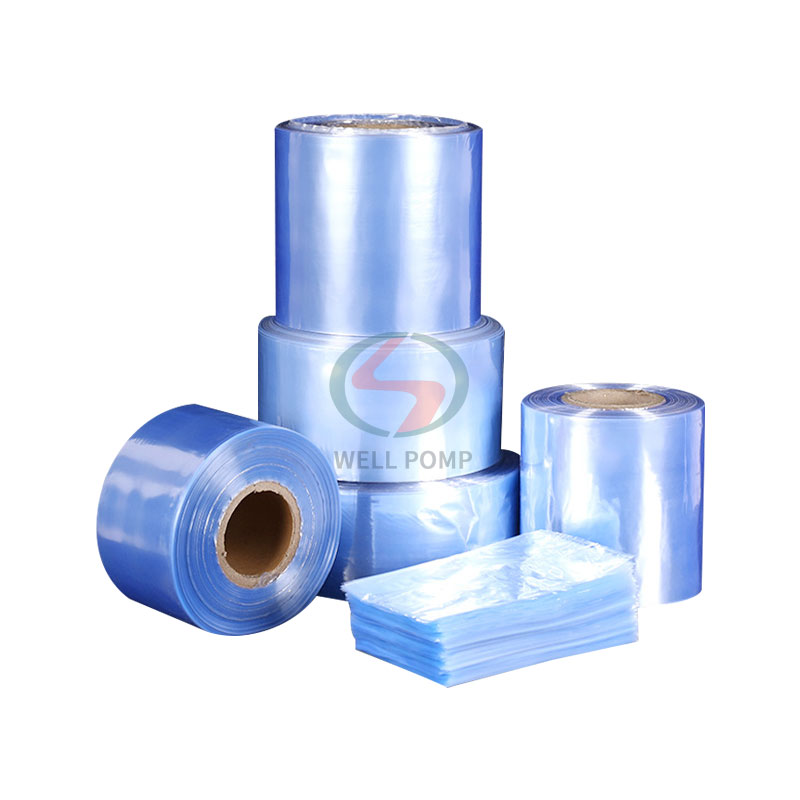

Heat shrinkable film is generally suitable for the whole package of wine, cans, mineral water, various beverages, cloth and other products. PVC shrink film is added with ingredients to enhance its heat resistance, toughness and ductility. The upper layer of this surface film is paint, the main component in the middle is PVC, and the lower layer is back-coated adhesive.

Heat shrinkable film is a good film packaging material, which has the following advantages:

1, a variety of commodities can be packaged in a heat-shrinkable packaging bag to prevent the loss of individual small commodities, which is also convenient for customers to carry;

2. heat shrinkable film with different mechanical strength and functions can be produced by selecting different resins and formulas, which can be used for inner packaging with low strength and light weight, and also for transportation packaging (outer packaging) of mechanical products and building materials for containers with good strength;

3, it is close to the appearance of goods, and can be applied to the packaging of goods with various shapes, and the contents of the packaging are common;

4, good transparency, allowing customers to directly see the packaged goods, which is convenient for customers to choose goods;

5. Excellent anti-theft and dustproof performance;

The heat shrinkable label is mainly gravure printing, and the printed graphics and texts are bright in color and good in saturation. Because it can decorate the packaging container closely, it can highlight the appearance of the goods and enhance the appearance decoration of the goods, which can produce a good shelf effect. In the process of labeling, the label and container can be integrated without using adhesive, which can realize the large-scale on-line operation of goods and reduce the production cost.

Heat shrinkable film is also the protection of building and transportation materials. It is not only suitable for the packaging of multiple products and packaging with pallets, but also convenient for transportation and sales, easy to realize mechanization and save labor and material resources, and can partially replace the packaging of cartons and wooden cases. Heat shrinkable film used bottled beer instead of strapping rope to prevent bottled beer from exploding and injuring people.

It has been widely used in fast food, ceramic products, tea sets, mechanical parts and other areas. It can be used for labels of various PET bottled beer and beverages, which can reduce the process of removing labels and facilitate recycling. It is of great significance to apply the combination of heat-shrinkable film and gas-phase antirust technology to replace antirust oil in machinery and hardware tools to enhance antirust ability.

In addition, the outstanding feature of heat shrinkable film is the phenomenon of shrinkage recovery. That is, when the heat shrinkable film is created, the heating well is stretched in the corresponding direction in advance, and then the inkstone is cooled, so that the chain molecules are arranged in the stretching direction. When the film is reheated to the quietness during stretching, the chain molecules return to the original disordered state, and the thin size also returns to the size before stretching, that is, the phenomenon of shrinking X is produced.