Production process of PVC heat shrinkable film

2023-08-12 17:52The production method of PVC heat shrinkable film is to produce thick cylindrical film or flat thick film by extrusion film blowing or extrusion salivation after resin particles enter the extruder. For crystalline polymers, in order to prevent and reduce the crystallinity, cooling water quenching method should be used to cool the thick film, because the crystallized thick film cannot be stretched in two directions or one direction, and stretching will destroy the crystallization and reduce the mechanical strength and performance of the film.

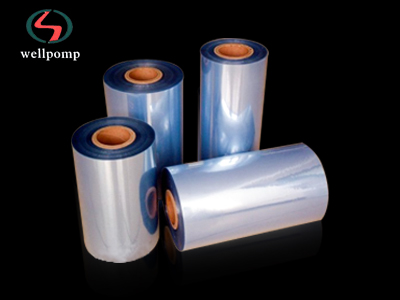

The produced thick film is reheated to the TG ~ TF temperature of the resin, that is, it is stretched mechanically in the longitudinal or transverse direction between the glass transition temperature and the melting temperature, and then cooled to become a heat shrinkable film. For amorphous polymers, such as PVC, it can be directly cooled from the molten state to the high elastic state, then stretched, cooled and coiled into PVC heat shrinkable film without quenching and reheating.

Because of its excellent transparency and easy modification, PVC can easily meet the requirements of different strength and packaging performance.

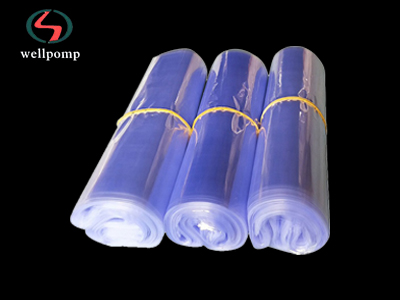

Because of its excellent electrical insulation and good self-extinguishing property, it is widely used in the production of heat shrinkable films, which are used for printing standard stems, shrink sleeves for wire and cable joints and shrink packaging.

The production process of PVC heat shrinkable film is as follows: unpacking PVC resin raw materials, inspection, screening, formulation-mixing → granulation → extrusion of thick film → air cooling → heating in hot water bath with boiling water → transverse inflation of setting cylinder → defoaming with film nip roller → winding into heat shrinkable film. In the production process of PVC in heat shrinkable film, there are different production formulas due to different uses of heat shrinkable film.