What are the precautions in the production of heat shrinkable packaging film?

2024-05-12 16:36What aspects should be paid attention to in the production of heat shrinkable packaging film?

1. Nowadays, many consumers pay attention to product information. When they buy products, they need to know important information such as nutritional components and functions, so that they can decide whether to buy products. Therefore, the labels of packaging bags should show these important information simply and clearly.

2. From the consumer's point of view, simple and clear label information will increase their trust in products, and they hope that food manufacturers can convey what they want to know to consumers through labels. According to the survey, 58% of customers will check the ingredient information, while more than three quarters are worried about using artificial agents.

3. Sight, touch, smell, taste and hearing can all attract consumers. Many manufacturers often put the visual element in front when considering the elements of packaging bags to attract consumers. However, it means that touch can mobilize people's senses, and touch can make consumers more willing to pay higher prices.

4. The method of increasing the sense of touch can use embossing, laser etching and other methods in printing. Although this will increase the time and cost of packaging bag production, these additional investments will help the product gain additional value. These special effects on the packaging bag can attract more attention from consumers.

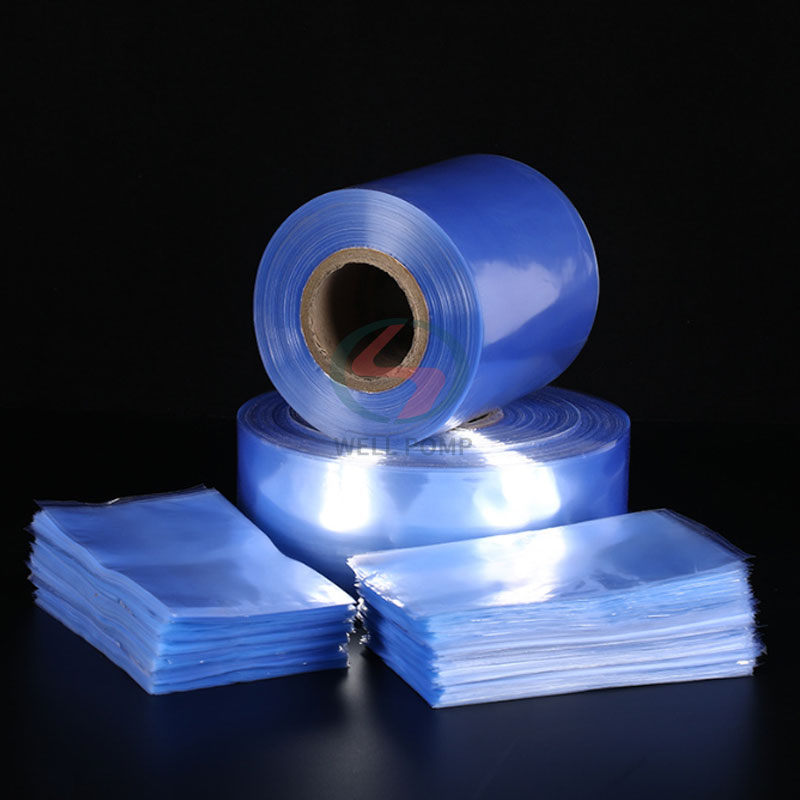

Heat shrinkable packaging film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Since heat-shrinkable packaging films are often suitable for outdoor use, it is necessary to add UV anti-ultraviolet agents. It has good flexibility, not easy to be damaged, strong blasting resistance, good impact resistance, good tear resistance and strong tensile force, and can replace box packaging.

The shrinkage rate is large, and the articles can be tightly wrapped after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency, light transmittance of 80%, can display products, can promote products invisibly, and also reduce distribution errors in logistics links. It is waterproof and dustproof, which can not only achieve the packaging effect, but also beautify and protect the products.

Heat shrinkable packaging film uses far infrared radiation to directly heat films of various specifications. The products are transported to the shrinkage furnace by conveyor belt, and the products are packed with shrink packaging film, sealed and then enter the shrink packaging machine, and the products automatically shrink. The power consumption of heat-shrinkable packaging machine is small, and the average hourly power consumption is only 2.1KW, which achieves the correct shrink packaging effect, and will never affect the packaging. The electronic stepless speed change, the solid-state voltage regulator controls the temperature and is stable, and it is applied to the heat shrinkage of food, beverage, candy, stationery, hardware tools, daily necessities, chemical products, etc.

Shrinkage film should be the selected shrinkage film.

1, each roll of conjunctival head is not more than one.

2. The film length can be 1500m~2500m per roll.

3. The longitudinal shrinkage can be controlled within 0 ~ 3, and the transverse shrinkage can be controlled within 48% ~ 53%.

4. The product is bright, and there is no obvious wrinkle and reinforcement explosion.

5, the film width can be from 20 mm to 140 mm..

6, the surface of the film can't have obvious drawing, stripes, crystal point per square centimeter can't be more than 1.

7, the film thickness can be from 0.02 ~ 0.08, can't have obvious one-sided plus or minus 0.02 mm..

Compared with other packaging processes, shrink packaging has the following main characteristics: beautiful appearance, close to the goods (so it is also called body-fitted packaging), and suitable for packaging of various shapes of goods; Good protection, if the inner packaging of shrink packaging is combined with the transportation packaging hanging on the outer packaging, it can have good protection; Good cleaning performance, suitable for packaging precision instruments and sophisticated electronic components; Good economy; Anti-theft is good, a variety of foods can be packed together with a large shrink film to avoid loss; The stability is good, and the goods will not stagger in the packaging film; Transparency is good, and customers can directly see the contents of the goods.