Characteristics of heat shrinkable film

2022-12-14 15:47The characteristics of heat shrinkable film are obvious. At first, it has good flexibility, is not easy to be damaged, and has good blast resistance. At the same time, it also has corresponding impact resistance. It is precisely because of these characteristics that people use it to package newly produced goods, in fact, it makes a protective film for the goods, which protects the appearance of the goods from being damaged, so as to enhance the impression in customers' minds. Heat shrinkable film is generally applicable to the whole package of wine, cans, mineral water, various beverages, cloth and other products. PVC shrink film with additional ingredients to enhance its heat resistance, toughness, ductility, etc. The upper layer of this surface film is paint, the main component in the middle is polyvinyl chloride, and the lower layer is back coating adhesive.

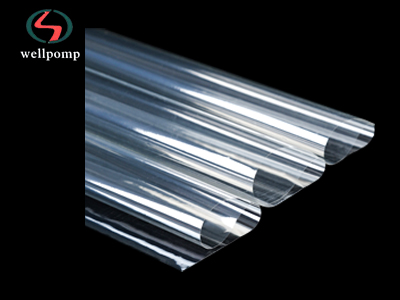

Shrinkage film is designed based on the principle of stretching orientation of polymer molecular chain, and formed by rapid cooling. Its physical principle is: when the polymer is in a high elastic state, it is stretched and oriented, then the polymer is quenched to below the glass transition temperature, and the molecular orientation is frozen. When the article is heated in the process of packaging, the stress relaxes due to the thermal movement of the molecule, and the molecule returns to its original state, resulting in contraction. This performance enables the heat shrinkable film to be smoothly attached to beverage bottles of various shapes, and ensures flatness and wrinkle-free. Therefore, it is important to test and control the thermal shrinkage of PVC heat shrinkable film.

Shrinkage film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film can not produce holes. Because shrink film is often used outdoors, it is necessary to add UV anti-ultraviolet agent. It has good flexibility, not easy to be damaged, strong explosion resistance, good impact resistance, good tear resistance and strong tensile force, and can replace box packaging. The shrinkage rate is high, and the articles can be tightly wrapped after thermal contraction. If the PE through bag (the opening at both ends of the bag) is made, after thermal contraction, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency, light transmittance up to 80%, can display products, can promote products invisibly, and at the same time reduce the distribution errors in logistics links. Moisture-proof, water-proof, dust-proof, which can not only achieve the packaging effect, but also beautify and protect products.

Heat shrinkable film uses far infrared radiation to directly heat films of various specifications, and the products are transported to the shrinkage furnace through the conveyor belt. The products are put on the shrinkage packaging film, and then enter the shrinkage packaging machine after sealing, and the products shrink automatically. The heat shrinkable packaging machine has low power consumption, and the average power consumption per hour is only 2.1KW, which achieves the correct shrink packaging effect and never affects the packaging materials. The electronic stepless speed change and solid-state voltage regulator control the temperature and are stable. It is applied to the heat shrinkage of food, beverage, candy, stationery, hardware tools, daily necessities, chemical products, etc.

At present, the application of heat shrinkable film in the domestic market mainly shows the following characteristics:

1. It has been widely used in fast food, ceramic products, tea sets, mechanical parts and other areas;

2. It is of great significance to apply the combination of heat shrinkable film and vapor phase antirust technology to replace antirust oil in machinery and hardware tools to enhance the antirust ability;

3. Heat shrinkable film is also the protector of building and transportation materials. It is suitable for the packaging of many products and the packaging with pallets, which is convenient for transportation and sales, easy to realize mechanization, saves labor and material resources, and can partially replace carton and wooden box packaging;

4. It is used for various bottled beer and beverage labels, which can reduce the process of removing labels and facilitate recycling;

5. It is used for bottled beer instead of binding rope packaging to prevent bottled beer from hurting people.