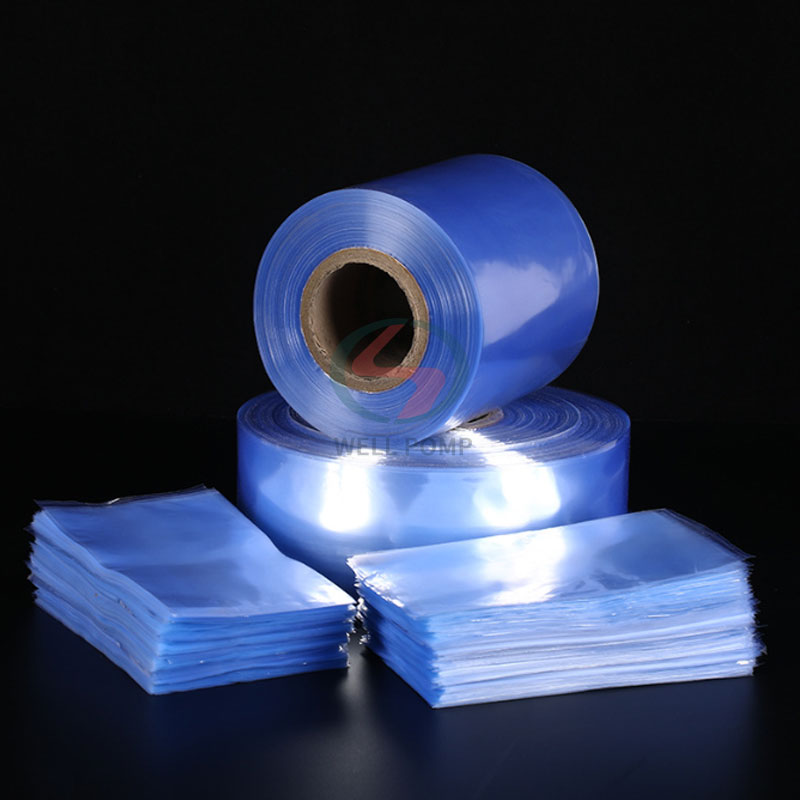

Characteristics of PVC heat shrinkable film and PVC packaging film

2024-05-15 15:30PVC heat shrinkable film has the characteristics of good transparency, good toughness, impact resistance, corrosion resistance and low water vapor permeability. When the film is exposed to some temperature, it automatically shrinks and tightly wraps the goods, thus achieving the functions of protecting the goods, rust prevention, pollution prevention, breakage prevention and theft prevention. The stability of commodity storage and transportation is good, and the packaging technology and equipment are simple, which is convenient for automatic heat-shrinkable packaging.

PVC is easy to break when printed in heat shrinkable film. It is not that the quality of PVC heat shrinkable film is not good, but that there is a solvent in the printing ink for PVC that will dissolve the PVC film, and the volatility of this solvent is small. Therefore, if there is too much solvent in the solvent for dissolving PVC in PVC ink, the PVC heat shrinkable film will be dissolved and broken during printing. However, if the printing ink for PVC is not used, the printing fastness is not good.

PVC heat shrinkable film can assemble the scattered goods into a whole, and it is also suitable for the packaging of single goods. Secondly, PVC heat shrinkable film clings to the surface of the package, which makes people feel sticky and makes the goods more beautiful, crisp and shiny. It is a wise choice to improve the competitiveness of goods. The important point is that PVC has low input and high output, which is why many businesses choose it. The surface protection of high-shielding products forms a light and shielding surface around the products, thus achieving the goals of dust prevention, water resistance and theft prevention. It is particularly important to compress the film packaging to make the packaged goods evenly stressed and prevent the uneven stress from harming the goods, which cannot be done by the traditional packaging methods (bundling, packaging, tape packaging, etc.).

PVC heat shrinkable film can be divided into soft PVC and hard PVC. Among them, hard PVC accounts for about 2/3 of the market and soft PVC accounts for 1/3. Shrinkage film can present more and more beautiful effect and stronger functionality. With the improvement of quality of life and the diversification of packaging film, the requirements for shrinkage film are getting higher and higher. heat shrinkable film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect products. Shrinkage film must have good puncture resistance, good shrinkage and corresponding shrinkage stress. During the shrinkage process, the film cannot produce holes, because shrinkage film is often applicable. Therefore, it is necessary to add UV anti-ultraviolet agent, which has good flexibility, not easy to be damaged, strong blasting resistance, good impact resistance, good tear resistance and strong tensile force, can replace box packaging, has a large shrinkage rate, and can tightly wrap articles after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency, light transmittance of 80%, can display products, can promote products invisibly, and also reduce distribution errors in logistics links. Not afraid of water and dust, it can not only achieve packaging effect, but also beautify and protect products.

PVC packaging film is used for the sale and transportation of various products, and its main function is to stabilize, cover and protect the products.PVC packaging film has good puncture resistance, good shrinkage and corresponding shrinkage stress.

Characteristics of PVC packaging film:

1. Recycling: The winding film can be recycled and granulated in the factory by using general recycling equipment. It can not only reduce environmental pollution, but also save the cost of recycling packaging.

2, no residue: tear off the protective film, there will be no residual text or glue.

3. Non-shedding: the viscosity is 1% higher than that of general enterprise products, and the protective film does not fall off when attached.

4. Reduce the overall packaging cost: replacing the traditional stretchwrapped film with film has obviously reduced the total amount of use, so its use cost, transportation cost and storage space cost have all decreased.

5, no degumming: use glue material, do not let the protective film become a burden that affects product quality.

6. It is convenient to use and the working speed is not bad: due to the winding film, it is pre-stretched, which is quite labor-saving, and the unused packaging machine and the used packaging site can be operated by men, women and children. Under the same weight, the length of each roll of this kind of wound film is more than twice as long as that of ordinary wound film, which can reduce the frequency of replacing film rolls during packaging and save costs in transportation, packaging and distribution.

7. Non-retraction: environmental temperature difference, surface stretching, resulting in protrusion at both ends. The protective film is made of good quality material. At high temperature, we don't compare it for a while, but look at the long-term quality.