Difference between PET shrink film and PETG shrink film?

2025-04-22 15:15PET shrink film

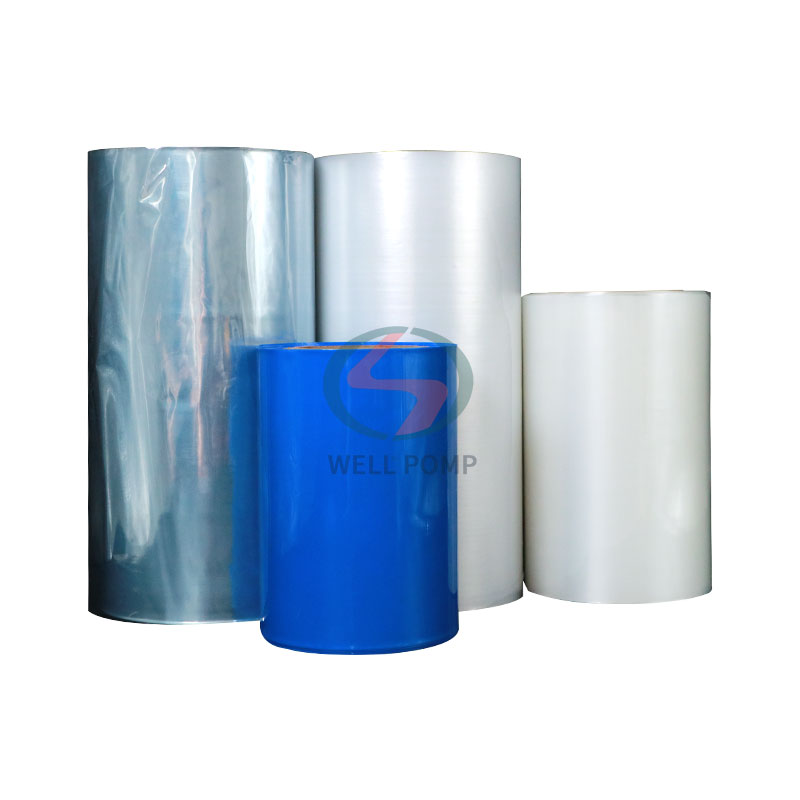

can be used as packaging materials for different foods, clothing, fertilizers, industrial products, and agricultural films. For example, shrink labels are its main application field. Because with the development of PET beverage bottles, beverage bottles such as cola, Sprite, and juice all need PET heat shrink film to match them as heat-sealed labels. They belong to the same polyester category. It can also be processed into composite films by extrusion for packaging heavy objects. It has high strength, low temperature resistance, moisture resistance, and good printability and processability.

1. Hollow products: High-density polyethylene has high strength and is suitable for hollow products. Such as milk bottles and detergent bottles;

2. Tube sheet: The extrusion method can produce polyethylene pipes. High-density polyethylene pipes have high strength and are suitable for underground laying. The extruded sheet can be processed twice. High-density polyethylene can also be made into low-foam plastics by foaming extrusion and foaming methods for tabletops and building materials;

3. Fiber: It is called ethylene in China. It is generally made of low-pressure polyethylene and spun into synthetic fibers. Ethylene is mainly used to produce fishing nets and ropes, or spun into short fibers and used as flakes. It can also be used for industrial acid-resistant and alkali-resistant fabrics.

4. Miscellaneous products: Miscellaneous products produced by injection molding include daily necessities, artificial flowers, turnover boxes, small containers, bicycle and tractor parts, etc.; refrigerator containers, storage containers, household kitchen utensils, sealing covers, etc.; high-density polyethylene is used to manufacture structural parts.

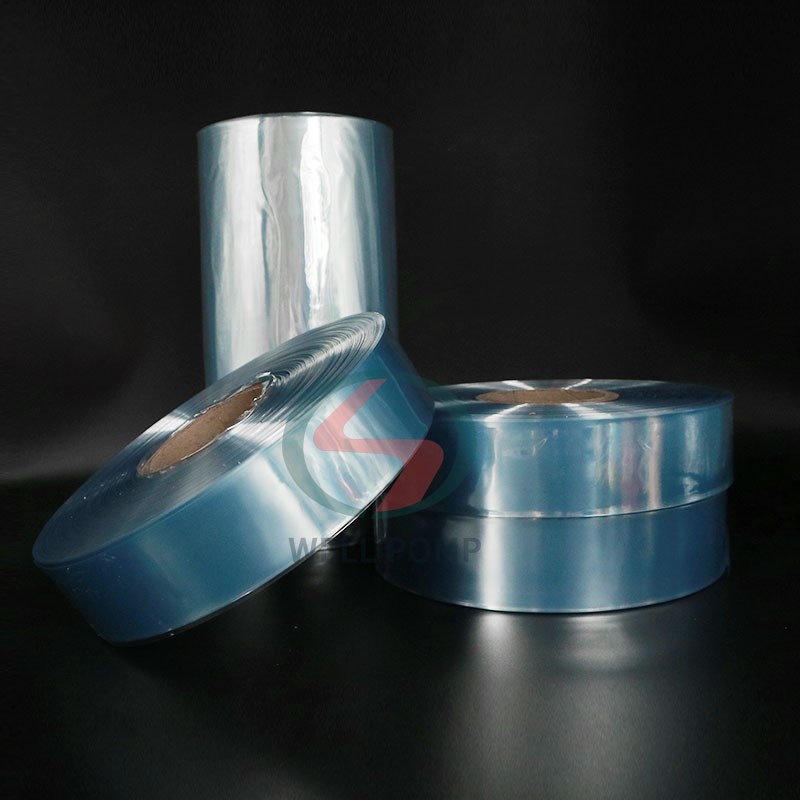

PET-G shrink film

Polyethylene Terephthalate Glycol-Modified (PET-G) is a thermoplastic polyester distinguished by its glycol-enhanced composition, achieved through glycolysis at a molecular level. Renowned for its superior performance, PET-G exhibits remarkable clarity and transparency crucial for applications requiring optical precision.

Surpassing standard PET films, PET-G excels in impact resistance, ensuring heightened durability. Its adaptability extends to diverse industries, finding applications in packaging, labels, graphics, and various industrial uses where a harmonious blend of optical clarity, durability, and chemical stability is imperative. The film boasts excellent chemical resistance and formability, facilitating manufacturing processes. Particularly favoured for heat-shrink applications, PET-G offers low shrink stress, high transverse shrink rates, low longitudinal shrink rates, and minimal haze, making it a preferred choice for heat-shrink films like shrink sleeves.