Production process of heat-shrinkable film

2023-12-05 12:01Production process of heat-shrinkable film

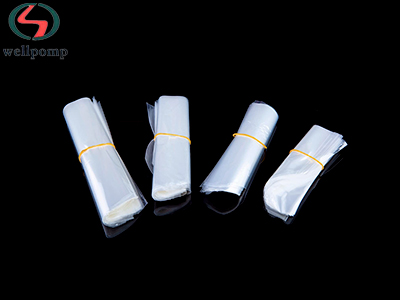

The heat-shrinkable film is a plastic film widely used in the packaging industry, which has strong shrinkability, good sealing performance and strong impact resistance. This article will introduce the production process of heat-shrinkable film.

Firstly, prepare raw materials.

Heat-shrinkable film usually uses polyolefin resin as the main raw material, such as polyethylene, polypropylene, etc. In addition, some additives such as antioxidants and UV absorbers are needed to improve the performance of the film.

Secondly, prepare the film.

Extruder melting and plasticization: Heat the raw materials in the extruder to melt and form a homogeneous plastic melt.

Film blowing: Blow the plastic melt into a thickness-uniform film through a film blowing machine.

Cooling and solidification: Cool the blown film to solidify and form a film with a certain shape and size.

Thirdly, heat shrinkage treatment.

Heat shrinkage furnace heating: Send the solidified film into the heat shrinkage furnace for heating, so that the film can shrink and deform when heated.

Cooling and solidification: Cool the film coming out of the heat shrinkage furnace quickly to keep its shape and size after shrinkage.

Finally, after-treatment.

Longitudinal and transverse stretching: Stretch the heat-shrinkable film in longitudinal and transverse directions to improve its physical properties and mechanical strength.

Surface treatment: Perform corona treatment or coating treatment on the surface of the film to improve its printing performance and bonding performance.

Cutting and packaging: Cut the treated film into different sizes according to customer requirements, and package it for use.

In general, the production process of heat-shrinkable film includes raw material preparation, film preparation, heat shrinkage treatment and after-treatment steps. Through the control of these steps, high-quality heat-shrinkable film can be produced to meet different needs.