What are the characteristics of heat shrinkable film application?

2023-09-23 16:34Heat shrinkable film can present more and more beautiful effects and stronger functions. With the improvement of the quality of life and the diversification of packaging films, the requirements for shrink films are getting higher and higher. heat shrinkable film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect products.

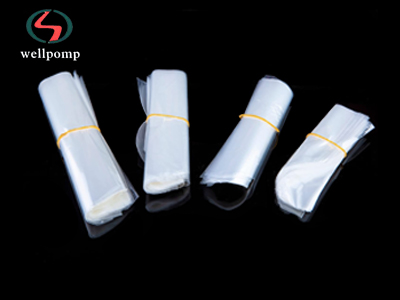

In the process of shrinkage, the film cannot produce holes. Because shrink film is often suitable for outdoor use, it is necessary to add UV agent. It has good flexibility, not easy to be damaged, strong blasting resistance, good impact resistance, good tear resistance and strong tensile force, and can replace box packaging. The shrinkage rate is large, and the articles can be tightly wrapped after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency and light transmittance can display products, promote products indirectly, and reduce distribution errors in logistics links. Not afraid of water and dust, it can not only achieve packaging effect, but also beautify and protect products.

Heat shrinkable film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Because heat shrinkable film is often used outdoors, it is necessary to add UV-resistant agent. It has good flexibility, not easy to be damaged, strong blasting resistance, good impact resistance, good tear resistance and strong tensile force, and can replace box packaging.

The shrinkage rate is large, and the articles can be tightly wrapped after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency, light transmittance of 80%, can display products, can promote products invisibly, and also reduce distribution errors in logistics links. Not afraid of water and dust, it can not only achieve packaging effect, but also beautify and protect products.

At present, the application of heat shrinkable film in the domestic market mainly shows the following characteristics:

1. It has been widely used in fast food, ceramic products, tea sets, mechanical parts and other areas;

2. It is of great significance to apply the combination of heat-shrinkable film and gas-phase antirust technology to replace antirust oil in hardware tools to enhance antirust ability;

3. Heat shrinkable film is also the patron saint of building and transportation materials. It is not only suitable for the packaging of multiple products and packaging with pallets, but also convenient for transportation and sales, easy to realize mechanization and save labor and material resources, and can partially replace the packaging of cartons and wooden cases;

4. It can be used to label various bottled beer and beverages, which can reduce the process of removing labels and facilitate recycling;

5, used for bottled beer instead of tying rope packaging to prevent bottled beer from hurting people;

Heat shrinkable film will shrink when heated, thus tightly covering the product. The materials used for heat shrinkable film are mainly various thermoplastic films. Mainly PVC shrink film, with the continuous development of market demand, PVC shrink film gradually decreases, while various multi-layer co-extrusion heat shrinkable films such as PE, PP, PET, OPP, PVDC and POF develop and become the mainstream of the market.

Accurate explanation: heat shrinkable film is a thermoplastic plastic film that is stretched and shaped in the production and processing process, but can be shrunk by heat during use. Usually, a thick film is produced by extrusion blow molding or extrusion tape casting, and then it is stretched longitudinally and transversely at a high elastic temperature above the softening temperature and below the melting temperature, or it is stretched in one direction only and not in the other direction. The former is called biaxial stretching shrinkage film, while the latter is called unidirectional shrinkage film. When in use, when it is higher than or close to the stretching temperature, it will shrink to wrap the packaged goods. A heat-shrinkable film is a bi-directional shrinkage film. Oh, it has good shrinkage in both the horizontal and vertical directions.