Difference between PE/PVC/POF shrink film

2024-05-30 15:30First, the definition is different:

PE film is a kind of material with good toughness, which can not be easily crushed by ordinary plastic crusher. Because PE film is soft and tough, it is not easy to be chopped, not to mention the high tool temperature at high speed, which will make LDPE melt and adhere to the blade. The granulation of PE can be directly put into the feeding port of the extruder in strips, and the PE film is dragged into the barrel by the shear force of the screw to be heated, melted and extruded for granulation. The first-class material recovered from PE can still be blown into film, used for non-food and medicine packaging, and also widely used in the production of Oxford leather and tarpaulin, which has a bright future.

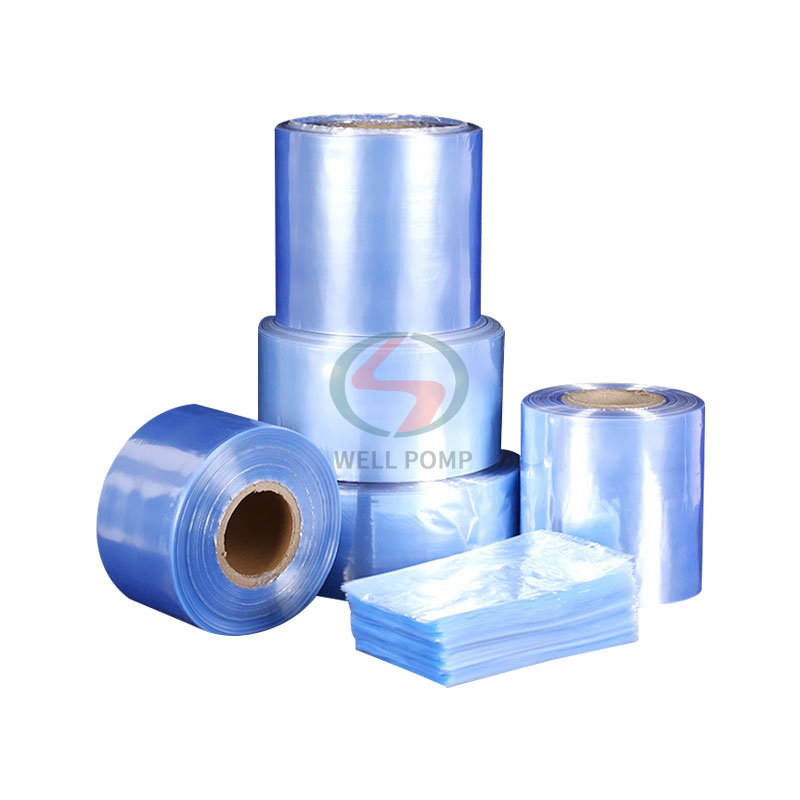

PVC and polyvinyl chloride are added with ingredients to enhance their heat resistance, toughness and ductility. The top layer of this surface film is paint, the main component in the middle is PVC, and the bottom layer is back-coated adhesive. It is a kind of synthetic material which is deeply loved, quite popular and widely used in the world today. Among the materials that can produce three-dimensional surface films, PVC is the most suitable material.

POF means heat shrinkable film, and POF is the full name of multi-layer coextruded polyolefin heat shrinkable film. It is made of linear low density polyethylene (LLDPE) as the middle layer and polypropylene (pp) as the inner and outer layers, plasticized and extruded by three extruders, and then processed by special processes such as die forming and film bubble inflation.

Second, the use is different:

PE heat shrinkable film is widely used in the whole package of wine, cans, mineral water, various beverages, cloth and other products. The product has good flexibility, strong impact resistance and tear resistance, and is not easy to be damaged, not afraid of moisture and has a large shrinkage rate.

Because of its unique properties (rain-proof, fire-resistant, antistatic and easy to form) and the characteristics of low input and high output, PVC film is widely used in building materials industry and packaging industry. Therefore, PVC film has the characteristics of high transparency, good gloss and high shrinkage.

POF is a kind of heat shrinkable film, which is mainly used for packaging products with regular and irregular shapes. Because of its non-toxicity, environmental protection, high transparency, high shrinkage, good heat sealing performance, high gloss, strong toughness, tear resistance, uniform heat shrinkage and suitability for full-automatic high-speed packaging, POF is the replacement product of traditional PVC heat shrinkable film.

Widely used in automotive products, plastic products, stationery, books, electronics, circuit boards, MP3, VCD, handicrafts, photo frames and other wood products, toys, pesticides, daily necessities, food, cosmetics, canned drinks, dairy products, medicines, cassettes and videos.