Explaining the application and performance of packaging film

2023-10-11 16:05Commodities need to be packaged during transportation, andpackaging film is often used, which can protect commodities and can be recycled when used.

1. When you buy packaging film, you should also look at the packaging film, whether it is not afraid of water and the packaging effect, whether it can protect the goods and look good.

2. When purchasing packaging films, you must first determine what type of packaging films you want to buy, because there are still many types of packaging films, and the performance advantages of different types of packaging films are different, so you should pay attention to them.

3. When the packaging film manufacturer reminds you to buy packaging films, you should also look at the specifications, quantity and type of packaging materials. It is more convenient to choose packaging films according to the packaging materials, and it can also protect the packaging materials well.

Stabilizers, lubricants, auxiliary processing agents, pigments, impact-resistant agents and other additives are often added to packaging films in practice. It has non-flammability, good strength, no fear of climate change and good geometric stability.

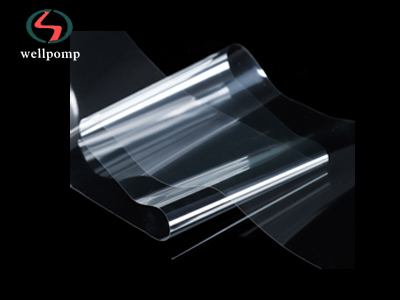

The packaging film has the characteristics of cleanliness, environmental protection, good transparency, high shrinkage, good heat sealing performance, high surface gloss, good toughness, high tear strength, uniform heat shrinkage and suitability for automatic packaging, etc. It is the replacement product of the old packaging film. At present, POFC-3 is widely used in the outer packaging of food, beverage, alcohol, electrical products, electronic products, toys, daily necessities and other products.

The main properties of packaging film are:

1. Mechanical properties: lightweight, practical and not afraid of scoring;

2. Processing performance: it is easy to adopt all the processing technologies in the current plastic processing. Such as injection molding, extrusion molding, plastic molding, calendering, rotational molding, plastic coating and so on;

3, chemical properties: not afraid of the atmosphere, chemical trial production and biological trial production, insulation performance, electricity resistance, heat insulation, noise elimination;

4, other physical properties: not afraid of water, fat, airtight, can collapse into hard or soft, transparent or opaque products according to requirements; Can be welded or heat sealed at high frequency; Easy to color and print;

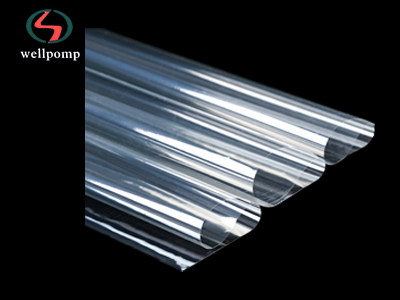

Some production processes of packaging films are not complicated. Ordinary production lines are generally composed of a rolling machine, a printing machine, a back coating machine and a cutting machine. The film with a thickness of only 0.3mm to 0.7mm is produced mainly through the direct stirring of the rolling machine, the rotation of the roller and high-temperature rolling. At the same time of production, colors are printed on the front of the film by the printing machine, and a layer of back coating is attached to the back of the film by the back coating machine.

Don't underestimate this back coating, it is an important determination of PVC film performance. The back coating is made of special materials and is an affinity agent. It is precisely because of this back coating that the pvc film can be tightly integrated with the medium density board or other boards, and it will not be opened for ten or even fifteen years. However, the problem of ordinary film sticking is that it can't solve the problem of film falling off. Because the whole production process is carried out at high temperature (the temperature in the roller reaches 220 degrees), PVC film has high light resistance and fire resistance.

Ordinary adhesive film is directly attached to the surface of the board with glue at room temperature, so after one or two years, the adhesive film is easy to fall off. The packaging film is pressed and attached to the surface of the plate by the vacuum film press at a high temperature of 110 degrees, so it is not easy to fall off.

Although the packaging film has excellent quality assurance, some people may say that PVC is a chemical product, but it just can't compare with natural materials, and it can't rule out toxicity and odor, and it will inevitably cause harm to the environment. This is not the case, because the raw materials for producing PVC film are specially refined, and all the bad substances are extracted, so PVC is all clean and odorless, and has no irritation to human skin or respiratory system. For those who are allergic to wood and paint, it is appropriate to use furniture or kitchen utensils packed with PVC film. By using PVC film as decorative film, people can use a lot of MDF, particleboard, plywood and fiberboard, and reduce the amount of wood used, thus reducing the damage to forests and even the environment. From this point of view, PVC film has made great contributions to the protection of ecological environment.