Explanation on the design process of packaging film

2023-10-07 15:57The packaging film is convenient to use and the working speed is not bad: due to the winding film, the pre-stretching technology is used, which is quite labor-saving, and the unused packaging machine and the used packaging site can be operated by men, women and children.

Under the same weight, the length of each roll of this kind of wound film is more than twice as long as that of ordinary wound film, which can reduce the frequency of replacing film rolls during packaging and save costs in transportation, packaging and distribution.

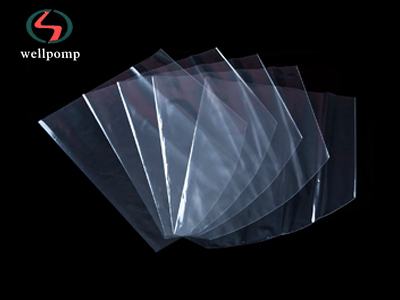

Product category: The products can be made into tubular film, L-shaped folded film and single film, and can be processed into barrel bag, flat pocket, trapezoidal bag, round arc bag, etc.

Product features: the packaging film is made of PVC resin by ethylene method mixed with more than a dozen accessories and then inflated twice. It is characterized by good transparency, easy shrinkage, freely adjustable shrinkage rate according to users' needs and strong operability.

The packaging film is made of vinyl PVC resin mixed with more than a dozen auxiliary materials and inflated twice. Its characteristics are good transparency, easy shrinkage, freely adjustable shrinkage rate according to users' needs and strong operability. Thermal shrinkable label printed matter is not only limited to small-area and single-line and color-block labels, but also more and more large-area multi-color and multi-purpose printed matter. Such as large-scale performance labeling, advertising, food and beverage labeling, price labeling, daily necessities, household appliances labeling and so on.

The packaging film is mainly designed by the principle of stretching orientation of high-fetching molecular chains. Its physical principle is that when the ionomer is in a high elastic state, it is stretched orientation. When the polymer is quenched below the glass transition temperature, the molecular orientation is frozen. At this time, when the article is packaged, due to the relaxation of molecular motion stress, the molecules will return to the original state and shrink. At present, there arePE shrink film, packaging film, PP shrink film, POF co-extrusion shrink film and so on in heat shrinkable film. In the big family of heat shrinkable packaging film, POF three-layer co-extrusion heat shrinkable film is a new generation product that has gradually emerged and been accepted by people in recent years.

Some production processes of packaging films are not complicated. Ordinary production lines are generally composed of a rolling machine, a printing machine, a back coating machine and a cutting machine. The film with a thickness of only 0.3mm to 0.7mm is produced mainly through the direct stirring of the rolling machine, the rotation of the roller and high-temperature rolling. At the same time of production, colors are printed on the front of the film by the printing machine, and a layer of back coating is attached to the back of the film by the back coating machine.

Don't underestimate this back coating, it is an important determination of PVC film performance. The back coating is made of special materials and is an affinity agent. It is precisely because of this back coating that the pvc film can be tightly integrated with the medium density board or other boards, and it will not be opened for ten or even fifteen years. However, the problem of ordinary film sticking is that it can't solve the problem of film falling off. Because the whole production process is carried out at high temperature (the temperature in the roller reaches 220 degrees), PVC film has high light resistance and fire resistance.

Ordinary adhesive film is directly attached to the surface of the board with glue at room temperature, so after one or two years, the adhesive film is easy to fall off. The packaging film is pressed and attached to the surface of the plate by the vacuum film press at a high temperature of 110 degrees, so it is not easy to fall off.

Although the packaging film has excellent quality assurance, some people may say that PVC is a chemical product, but it just can't compare with natural materials, and it can't rule out toxicity and odor, and it will inevitably cause harm to the environment. This is not the case, because the raw materials for producing PVC film are specially refined, and all the bad substances are extracted, so PVC is all clean and odorless, and has no irritation to human skin or respiratory system. For those who are allergic to wood and paint, it is appropriate to use furniture or kitchen utensils packed with PVC film. By using PVC film as decorative film, people can use a lot of MDF, particleboard, plywood and fiberboard, and reduce the amount of wood used, thus reducing the damage to forests and even the environment. From this point of view, PVC film has made great contributions to the protection of ecological environment.