Selection and basic conditions of heat shrinkable film

2023-11-04 18:15Customers who choose heat shrinkable film usually consider the specific selection mode from the cost at first. Heat shrinkable packaging and laminating film can usually achieve the same packaging effect, so how to decide which packaging film to choose?

Generally speaking, the main differences are the requirements for packaging patterns, the frequency of packaging, the requirements for shelf life, and the physical characteristics of the packaging itself such as liquid, powder, granular, solid, square and so on. The following criteria help customers to choose suitable packaging materials: the size of food factories; Whether the service object is industrial system or retail industry; Adjustment requirements; Shelf life requirements; Anti-abuse requirements; The shape of the product; Whether it is used for preservation, freezing or other environmental requirements; Consistency between packaging production company and customer culture.

Four basic conditions for shrink film.

1. Separation performance

Regarding the separation performance of pvc heat shrinkable film, the evaluation and characterization of separation function are different due to different membrane processes and different media to be separated. For all shrink films, the main consideration should be: having selective permeability to the separated mixture means having separation ability. The separation ability mainly depends on the chemical characteristics of pvc materials and the morphological structure of the separation membrane, and is also related to some operating conditions in the membrane separation process. The separation ability should be moderate, because the separation performance and permeability of the membrane are interrelated. If separation is required, part of the flux will be sacrificed, which will increase the operating cost.

2. Physicochemical stability

Physical and chemical stability of pvc heat shrinkable film The physical and chemical stability of the film mainly depends on the materials constituting the film, that is, it is determined by the chemical characteristics of the film materials. The physical and chemical stability of the membrane mainly includes heat resistance, chlorination resistance, microbial decomposition resistance, surface properties (charge or surface adsorption, etc.), hydrophilicity, hydrophobicity, electrical properties, toxicity and mechanical strength.

3. Permeability

The permeability of pvc heat shrinkable film is related to its separation performance, which is the main sign of its ability to treat separated media. Generally speaking, it is hoped that after the required separation rate is reached, the greater the flux of the separation membrane, the better. Permeability first depends on the chemical characteristics of pvc heat shrinkable film material and the morphological structure of separation membrane; The pushing factor also has a great influence, which increases with the potential difference (such as pressure difference, concentration difference, potential difference, etc.) in the separation process. The color response of the membrane is much greater than that of the separation performance. There is a linear relationship between many membrane separation processes and pressure difference in the range.

4. Economy

The economy of pvc heat shrinkable film plays an important role in practical application. The price of pvc in heat shrinkable film can't be too expensive, otherwise it can't be used in production. The price of pvc heat shrinkable film depends on two aspects: materials and manufacturing technology.

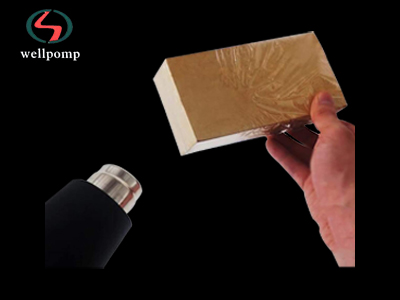

PVC heat shrinkable film is made by mixing PVC resin by ethylene method with more than a dozen auxiliary materials and then inflating for the second time. Its use method is to calculate the circumference according to the size of the wrapped object, convert the folding diameter (folding diameter =1/2 circumference), and then appropriately enlarge the folding diameter. PVC heat shrinkable film selects proper PVC heat shrinkable sleeve film according to the product specifications of our factory. Install the sleeve film on the package at the temperature of 100℃-160℃ for 6-10 seconds (the actual temperature of the sleeve film is 86℃, and the temperature rise of the package is less than 10℃).

1. Heat shrinkable packaging has good sealing, anti-fouling and anti-rust effects, which can prolong the storage period of food, facilitate storage and facilitate open-air stacking.

2. heat shrinkable film has high transparency, so the label has bright color and good luster.

3. heat shrinkable film can provide 360-degree decoration for packaging containers, and can print commodity information such as product description on labels, so that consumers can understand the performance of products without opening the packaging.

4. Heat shrinkable packaging can package special-shaped products that are difficult to package by ordinary methods.

5. heat shrinkable film is close to the goods after shrinking, and the packaging is compact and can show the appearance of the goods, and the packaged goods are beautiful.

6, shrink film performance is good, but also has a good strength, accept the weight of the contents.