Shrinkage film of outer packaging product

2023-12-22 12:01Shrinkage film has the characteristic of shrinking when heated, and it will shrink when heated, thus tightly covering the surface of the packaged article. At the same time, it also has the characteristics of good transparency, water resistance, good pollution prevention ability and good electrical insulation performance. Ordinary polymer materials, such as polyethylene and polyvinyl chloride, are usually linear structures, which will have a special "memory effect" after being transformed into a network structure by radiation from radioactive sources such as electron accelerators, and the expanded and cooled materials can shrink back to their original shapes after being heated.

Shrinkage film can be used for insulating packaging of electrical appliances and electronic components (such as the outer packaging of dry batteries); Packaging of general goods and packaging of food contact. Using it as packaging material can not only simplify the packaging process and reduce the packaging volume, but also show the color and shape of the packaged goods clearly because of the shrink transparent film, so shrink film is widely used in commodity packaging.

Shrinkage film has large diameter, light weight, outstanding flexibility and good bending performance, etc. It is mainly used for packaging products with regular and irregular shapes. Widely used in automotive products, plastic products, stationery, books, electronics, circuit boards, MP3, VCD, handicrafts, photo frames and other wood products, toys, pesticides, daily necessities, food, cosmetics, canned drinks, dairy products, medicine, cassettes and videos.

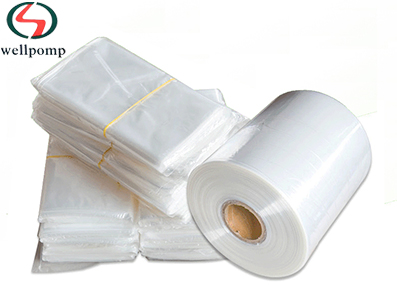

Shrinkage film is used in the sales and transportation of various products. Its main function is to stabilize, cover and protect products. Shrinkage film should have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. It has the characteristics of high transparency, good gloss and good shrinkage. It can be made into tubular film and L-shaped folded film as required, and can be processed into tube bags, flat pocket and other products.

Shrinkage film is made of PVC resin mixed with more than a dozen auxiliary materials and inflated twice. Its characteristics are good transparency, easy shrinkage, good strength, freely adjustable shrinkage rate according to users' needs and strong operability.

Shrinkage film can be made into tubular film, L-shaped folded film, and can be processed into tubular bag, flat pocket, etc.

Advantages of shrink film:

1, resin and auxiliary materials with good performance can be utilized, and the requirements of different users can be met in a large range;

2, the elastic tensile force is large, the goods with any geometric shape can be tightly wrapped, and the damage to the goods caused by bundling can be avoided, and it has good anti-loosening, rain-proof, dust-proof and anti-theft effects;

3. Stretch packaging saves raw materials than shrink packaging, and there is no need for heat shrink packaging machine to save energy;

With the increase of polycondensation reaction temperature, the polycondensation reaction time of shrink film is shortened, but when the reaction temperature exceeds 282℃, the color of polymer becomes worse. But the temperature is low, the reaction time is prolonged, and the hue is not good. Accordingly, the optimum reaction temperature in this study is (278 2)℃.

1. In a 5L reactor, using PTA, EG and HD as raw materials, modified polyester chips with good color can be synthesized for heat shrinkable film.

2. The better catalyst for the novel copolyester is a composite catalyst such as tetrabutyl titanate.

3. The esterification temperature of the new copolyester is 235 ~ 240℃, the polycondensation temperature is (278 2)℃, and the low vacuum time is about 10min longer than that of ordinary polyester.

4. The novel copolyester is suitable for film drawing, and the optimal feeding ratio is n (HD) ∶ n (EG) = 25: 75.

Antimony acetate was used as catalyst in the synthesis of polyester for heat shrinkable film, and its catalytic effect was better. Therefore, antimony acetate was chosen as the catalyst for the synthesis reaction in this study. However, it was found that the catalytic activity of antimony acetate on the synthesis reaction system was low, and the polymerization reaction could not be carried out when the addition amount of HD reached 20%.

In order to improve the influence of catalyst on the synthesis reaction, tetrabutyl titanate with good activity was used. Because tetrabutyl titanate made the chip yellow, the catalyst with improved hue was selected, and a composite catalytic system with titanium as the main component was formed in the later stage.