The excellent characteristics of PVC heat shrinkable film bring a lot of convenience to the people.

2023-07-06 17:01The main raw materials of PVC heat shrinkable film include polyethylene, polypropylene, polypropylene copolymer and sexual additives. These raw materials are environmentally friendly, and the product hygiene meets the world environmental protection standards. The life process will not pollute the environment, and there is no toxic gas and odor when applied. It is used for food packaging.

PVC heat shrinkable film is often used in food packaging because of its high transparency, good viscosity and elasticity, and low cost. However, this material may have a specific impact on people's health due to the addition of processing AIDS such as plasticizers and stabilizers. Generally, PVC cling film cannot be used to contact foods with high fat content and high temperature.

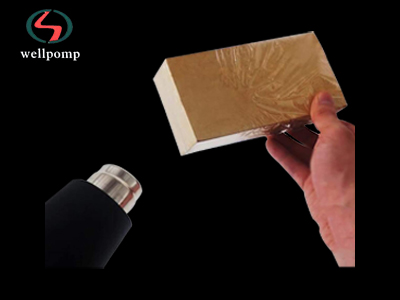

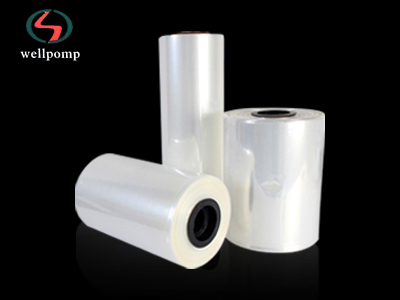

Principle of pvc heat shrinkable film Production The stable state of polymer chain tends to curl. When the polymer is in a high elastic state when heated and melted, the orientation of the polymer chain is stretched and straightened under the action of external force, and the orientation state of the polymer chain is frozen after rapid cooling reaches the glass transition temperature. When the temperature rises again, the polymer chain tends to be stable and curls, which is macroscopically manifested as contraction. According to its shrinkage principle, there is no chemical change, so it is called "physical reducibility". The PVC heat shrinkable film made by blow molding is made by using the above principle, and after two times of inflation and cooling. PVC heat shrinkable film is a popular new packaging material, which has good transparency, good toughness and low water vapor transmission. There is also an ideal shrinkage rate. When the film is subjected to a specific temperature, it automatically shrinks and tightly wraps the goods, thus protecting the goods, and also playing the roles of rust prevention, pollution prevention, injury prevention and theft prevention. Commodity storage stability, simple packaging technology and equipment, easy to realize automatic shrink packaging. PVC heat shrinkable film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect the products. Shrinkage film has high puncture resistance, good shrinkage and specific shrinkage stress. In the process of shrinkage, the film cannot produce holes. Because pvc heat shrinkable film is often used outdoors, it is necessary to add UV-resistant agent.

Pvc heat shrinkable film has high flexibility, is not easy to be damaged, has strong explosion resistance, impact resistance, tear resistance and strong tensile force, and can replace box packaging. PVC shrink film, adding ingredients to enhance its heat resistance, toughness, ductility and so on. The upper layer of this surface film is paint, the main component in the middle is PVC, and the lower layer is back-coated adhesive. It is a kind of synthetic material which is deeply loved, quite popular and widely used in the world today. Among the materials that can produce three-dimensional surface films, PVC is a more suitable material.

General packaging grade PVC heat shrinkable film can be made into tubular film and L-shaped folded film as required, and can be processed into tube bags and flat pocket. Although general packaging grade PVC heat shrinkable film can also be used for printing, the printing effect is not good, and there are few printable colors, and one or two colors are generally printed.

PVC heat shrinkable film is an excellent film packaging material, which has the following benefits:

(1) excellent transparency, which enables customers to directly see the packaged products and facilitate customers to choose products;

(2) It is close to the product shape, and can be applied to the packaging of products with various shapes, with a wide range of packaging contents;

(3) Excellent anti-theft and dustproof performance;

(4) A variety of products can be packaged in a heat-shortened packaging bag, which avoids the loss of a single small product and is convenient for customers to carry;

(5) Choosing different resins and formulas can produce environmentally-friendly shortened films with different mechanical strength and functions, which can be used for inner packaging with lower strength and smaller product weight, and also for transport packaging (outer packaging) of mechanical products and building materials for containers with higher demand strength. In the production process, PVC thermal shortening film is stretched in high temperature environment and then cooled sensitively, and then it reaches the purpose of setting. When heated again during use, it retracts to its original posture, and the heating is uneven, the shortening degree and planning are not the same. The production of PVC thermal shortening film should first choose extrusion blow molding or extrusion tape casting to produce thick film, then fully soften it at melting temperature, and then draw it horizontally and vertically.